- #Cetus3d z banding how to

- #Cetus3d z banding free

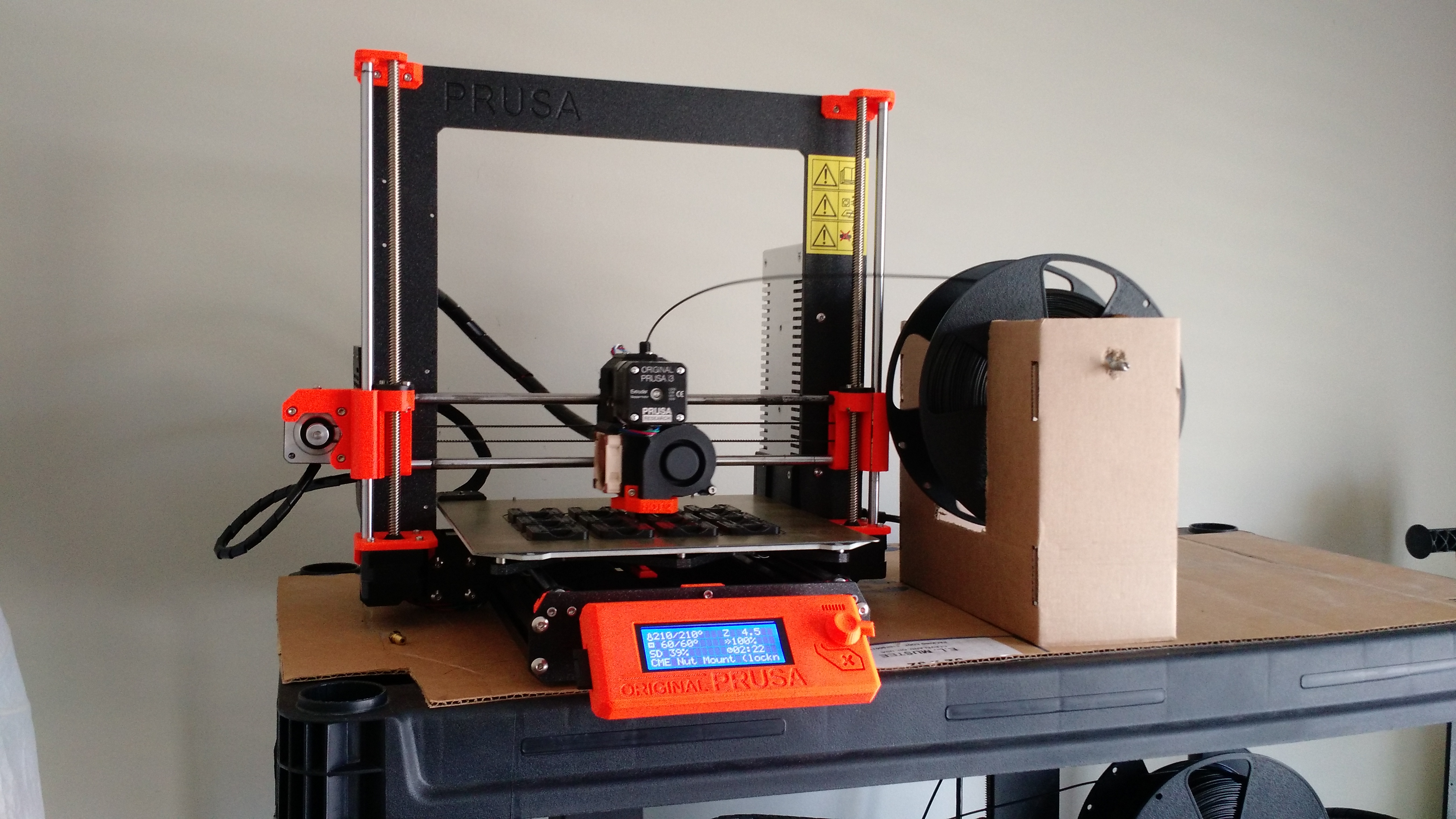

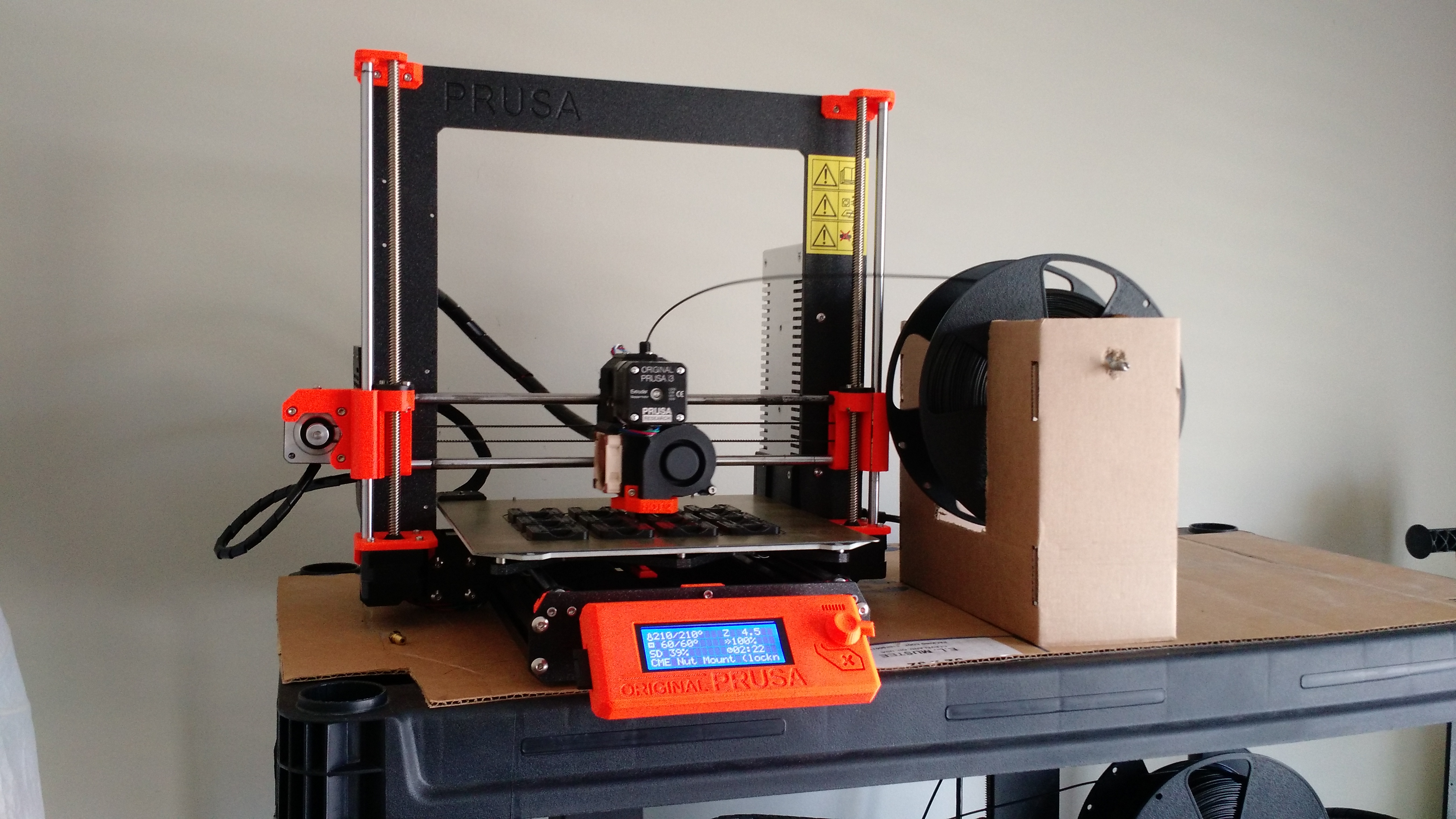

Manufacturers emphasize the positive qualities, reviews are skewed based on individual experiences and articles rarely give you insight into the author’s background. The question is, how do you decide on just one when so many choices are available? With dozens of factors to consider, many shoppers find themselves falling down the rabbit hole, comparing features, checking reviews and reading a myriad of articles to find the best 3D Printers.Īlthough researching your options is important, much of the information available is heavily biased. Many individuals are also experiencing the same issue, and there are many causes of this banding.Whether you are a complete beginner in search of your first 3D Printer, or an experienced hobbyist looking for a new machine, there is certainly no shortage of options to choose from. If you are experiencing the frustration of Z banding, you are not alone.

#Cetus3d z banding free

Ensure that your wires are clean and free so that they do not bind or pull.

In that case, the resistance will cause the axis not to move enough in some layers (making them short and wide) and then will catch up in other layers (making them tall and narrow). On a cantilevered Z axis, this can be caused by wire binding or pulling. Irregular variation in layer height is caused by the extruder platform or the extruder not maintaining the proper height while you are printing. Irregular variation in layer height causing Z banding

Ensure your printing temperatures are as uniform as possible. Complete your prints in an area that remains at a consistent temperature. Sometimes even your platform will expand and bow as its heats, and that is enough to impact the layer height and cause Z banding. These temperature shifts can cause some layers to spread out more than other layers due to the fact that they are extruded too soft. Temperature swings, even small ones, can lead to Z banding. Inconsistent temperature causing Z banding A tighter tolerance will lead to a more uniform filament diameter. Check the tolerance ratings of the filaments that you buy. Sample the filaments of new suppliers before purchasing large batches of filaments. Some low-quality filaments even have bubbles down the center, which will impact the cross-sectional area of your filament. Nonuniform filament diameter can cause inconsistent extrusion, so it is important that you ensure your diameter is as uniform as possible. Your filament diameter should be uniform so that there is not any variation in how it presses against the drive gear or how fast it feeds. #Cetus3d z banding how to

Novice Expert on YouTube has a wonderful tutorial that goes over how to create your own coupler to fix Z banding, and you can find the tutorial here ]. In order to do this, you need some calipers and some sort of CAD software to model in. The fix for a bad coupler is simple, 3D print a new one. Z banding can also be caused by your lead screw being misaligned, and this can lead to Z banding that directly matches up with the thread of your lead screw.īut what if my lead screw is already straight? If you have verified that your lead screw is straight, but you are still getting the Z banding, you are really having an issue with your coupler.

A Capricorn tube is a low friction bowden tube to help you with this. You can pick up a cheap and readily available 0.17 inch HDPE tube at your local Home Depot that will work just fine for this purpose. What you choose doesn’t have to be as low-friction as a Bowden tube, but it needs to be loose around the filament as to not increase friction. Run your filament through a low-friction tube or fixed structure from the extender to the spool. This is repeated over and over to create the Z banding. In this case, the filament will pull until there is enough force to pull it loose, and then the extruder will fall back into its normal position. This error is perhaps the most common cause of Z banding, and it happens when there is resistance from the spool pulling against the extruder, which then lifts the extruder up. Resistance from the spool causing Z banding We have highlighted some of the main causes of z banding and how to fix it. Are you experiencing Z banding? Never fear. It gives your prints an unpleasant look, rough texture, and reduces the bonding strength between the layers. Z banding is a periodic pattern in your 3D printed layers that often resembles a bumpy ribbing look.

0 kommentar(er)

0 kommentar(er)